CONATECwww.conatec.com

CONATEC

C\ Gabiria nº 112-114-146

Pº Ventas 20305

Irún (Guipúzcoa) SPAIN

Tel.: +34 943 633 562

Fax: +34 943 633 285

E-Mail: conatec@conatec.com

C\ Gabiria nº 112-114-146

Pº Ventas 20305

Irún (Guipúzcoa) SPAIN

Tel.: +34 943 633 562

Fax: +34 943 633 285

E-Mail: conatec@conatec.com

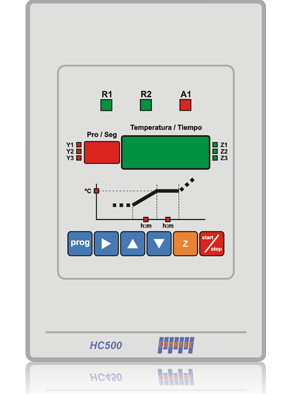

HC 500

Program regulator

Program regulator

Designed to be used in electric, gas and diesel ovens which require processes with different temperature levels, where it is necessary to control up to three areas of the oven, relating the consignments.

General Characteristics

- Box or panel assembly.

- Capacity to store up to 30 programs, each made up by an optional waiting time and a maximum of 30 segments. Each segment has a ramp and a plateau to maintain the temperature.

- Up to three configurable control outputs by relay or 4-20mA.

- Two alarm outputs by configurable relays.

- Incorporation of high temperature security module with an independent output.

- Possibility to block user access to security temperature.

- Permanent display of the temperature reading, the segment being performed, the state of the output control and the two alarms.

- Dynamic graph of the program execution.

- Possibility to program the gradients in ºC/h or by temperature and time.

- PID regulation or ON/OFF with adjustable hysteresis.

- Indication of broken thermocouple.

- Indication of power failure.

- Indication of inverted thermocouple.

- Configurable for K, S and R thermocouples.

- Input of external signal to force the segment to pass.

- RS-485 remote connection.

- Remote communication by internet by means of the CONATEC SW600 software.

Electrical

- Power: 230VAC. +/-20% (50+60Hz.).

- Consumption: 2.8VA.

- Alarm and control outputs by means of power free relays.

- Recommended operating temperature between 0 and 60ºC.

- Relative humidity of operation between 0 and 80% without condensation.

- EC standards.

Mechanical

- Vertical format.

- Dimensions 139.07x209.55x50mm.

- Front protection IP54.

Attached archives:

-

HC500

[295Kbs.]

HC500

[295Kbs.]

We use our own and third party cookies, for the analysis of user navigation. If you continue browsing, we consider that you accept the use.

You can change the settings or get more information here.